ZincTape®

It is designed to coat the surface of iron, steel, aluminum, light alloys, etc. in order to protect against corrosion attacks. This is done by contacting the zinc tape – pressed with appropriate force – with the protected surface.

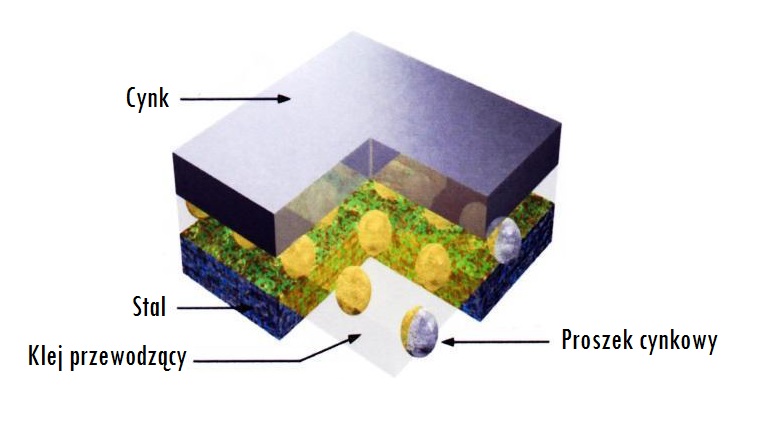

This method is commonly known as “laminar zinc coating”. The adhesive layer, applied to only one side of the zinc strip, consists of an adhesive matrix and the correct percentage of zinc powder with the appropriate grain size. After adding powders and special additives, the adhesive was properly electrically conductive.

Having this property is of paramount importance as it allows the adhesive to establish an electrical connection between the protected surface and the ZincTape® so that it can act as a galvanic anode.

Due to its particular manufacturing process and the high purity of the zinc used, ZincTape® presents an absolutely homogeneous and isotropic microstructure in all directions, unlike other protective systems. This property avoids pitting and other local attacks of corrosion.

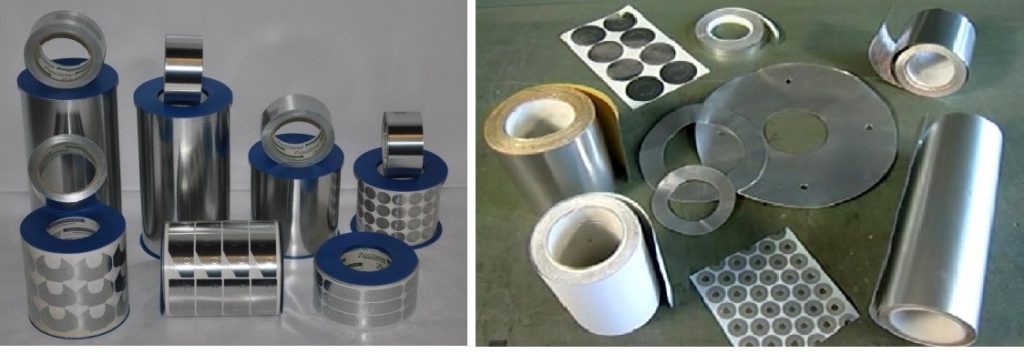

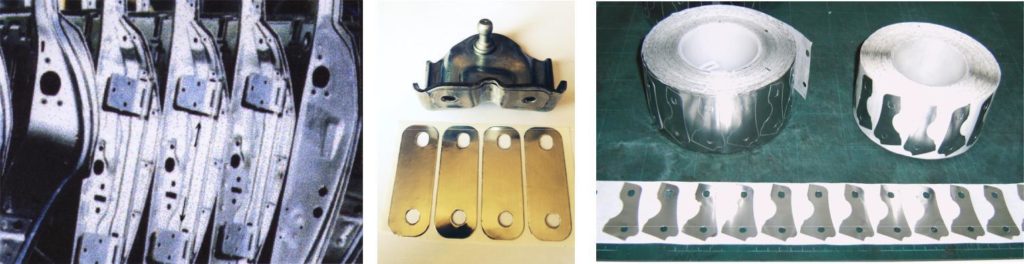

The product can be delivered in two forms:

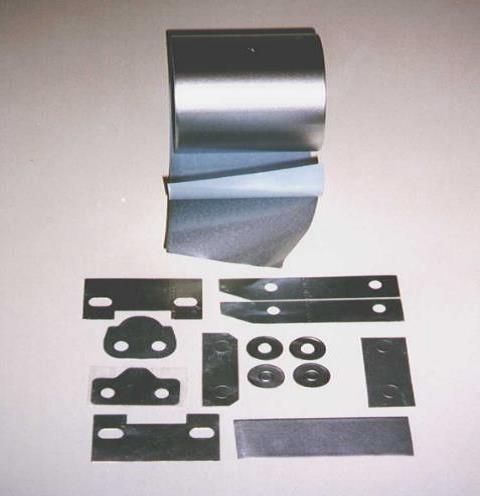

- cut shapes – according to the customer’s needs, e.g.

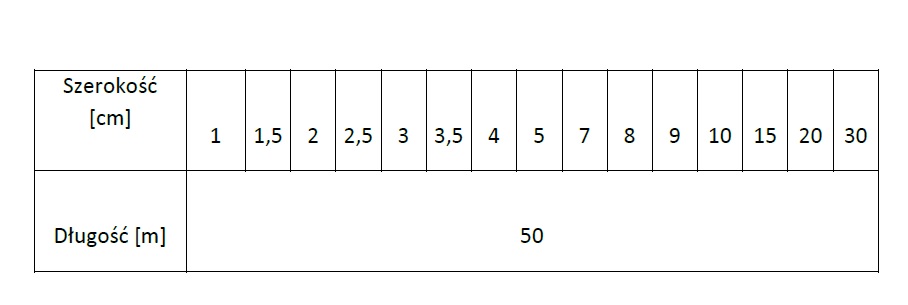

- rolls according to the diagram below:

Usage

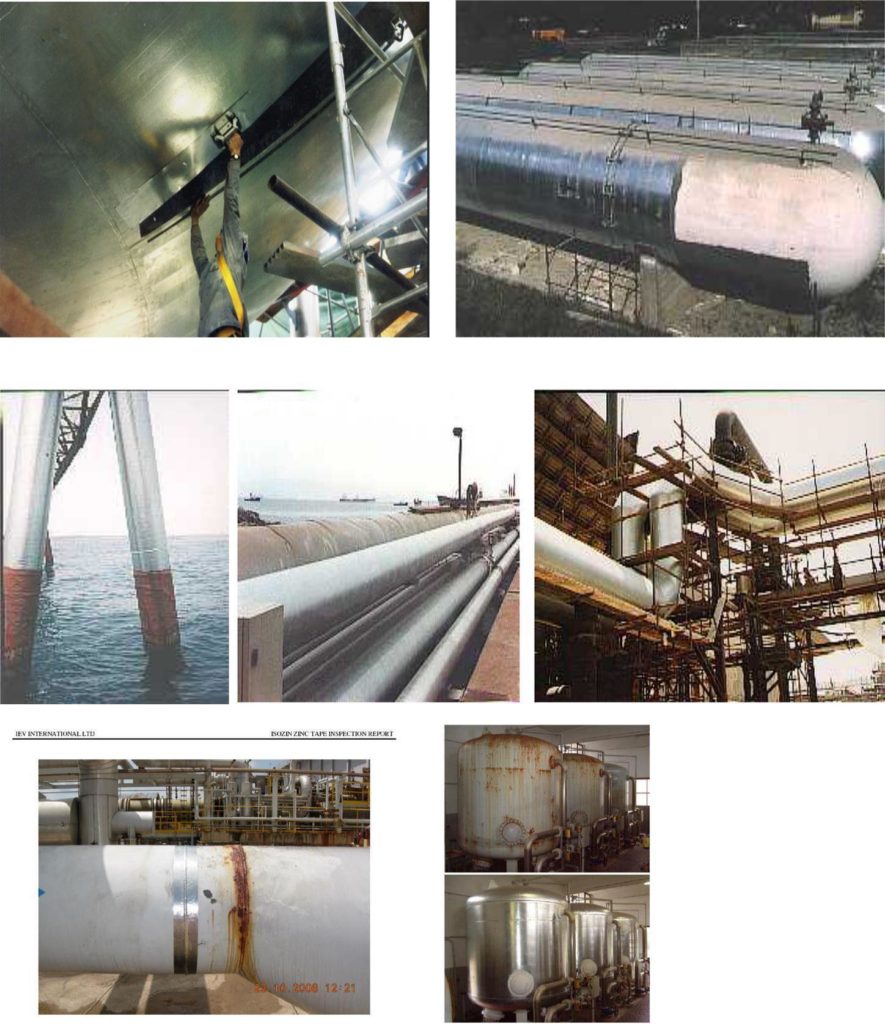

- Industry -> Tanks, activated carbon filters, aqueducts, rails, steel structures exposed to the open air.

- Refining and gas industry -> Above ground pipes and piping systems, bundles of pipes and insulated cables, offshore platforms, load-bearing platforms and poles, off-shore structures, power plants and combined heat and power plants.

- Lighting and traction poles -> Protection of metal supports applies to both covering the entire structure and covering the area of connection of elements (welds, bolted joints, riveted joints …). The coating is usually applied directly by the manufacturer of the metal supports.

- Strengthening the banks of rivers, lakes and other water reservoirs as well as water intake.

Zincofix®

Zincofix® is designed to cover the surface of iron, steel, aluminum and light metals in order to protect them from corrosion. This is achieved by pressing it on the surface that needs to be protected from corrosion. This method is commonly known as “Laminar Zinc Coating” The adhesive coat, which is applied only on one side of the Zincofix®, consists of a matrix of adhesive and a percentage of zinc powder. Through the addition of zinc powder and particular additives we have achieved the most important effect, which is making the adhesive itself electro conductive. This process allows the adhesive to create an electrical couple between the surface that needs to be protected and the Zincofix®, so that the zinc can act as galvanic anode.

The coating with our zinc layer assures a cathodic protection of metallic surfaces for a time, that, in most cases, is equal or longer than the lifetime of the structure to be protected.

Usage

- Railway -> Protection of window edges, vehicle supports, roofs and areas through which water can penetrate and stand.

- Automotive -> Protection of hinges and doors; in this particular case, Zincofix® is cut to obtain shapes that match the details and then glued onto the protected surfaces.

DoubleShield 3.3

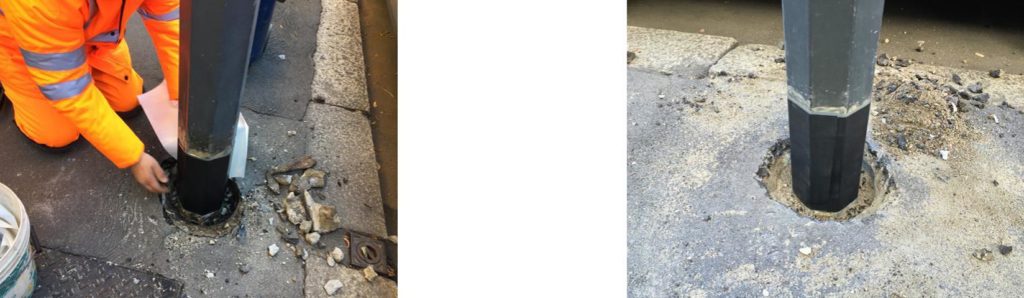

The anticorrosion tape DoubleShield 3.3 is a new concept of technology based on a double active-passive protection barrier. The product is a compound between two different layers of material: a sacrificial anode as inner layer and a sealing membrane as outer layer. The result is an unique and effective product that provides active protection to the metal surface that has to be covered with, and a physical-chemical passive protection. “Metalnastri DoubleShield 3.3” is a free solvent and environmentally friendly. It is designed to protect permanently underground structures, providing protection for the life-span of the same and virtually avoiding any future maintenance.

Three dimensions of protection in one product:

Active protection: galvanic anode;

Passive protection: provided by a membrane that adheres perfectly to the zinc, seals it and protects it from external damage;

Chemical protection – the special composition of the outer coating provides a special chemical resistance to all aggressive substances that naturally occur in soils.

The product DoubleShield 3.3 is a coupling between an electro-conductive adhesive laminar zinc tape with the main purpose of active protection, and a self-adhesive membrane made from a polymer-modified bitumen with a HDPE carrier foil that performs as external sealing, working as a barrier for physical and chemical protection.

Main uses

- steel pole for the public lighting;

- underground pipes;

- underground steel storage tanks;

- joining under and above-ground steel structures

More information on our partner’s website – Metalnastri S.r.l.: https://www.metalnastri.it/en/index.html